-

tel:

+86-15371113672 -

WhatsApp:

+86-15371113672 -

email:

qianli@jsryan.com

What Safety Features Should in a Non-Standard Custom Electric Thermal Oil Heater?

News List

- Petroleum and Gas

- How Do You Maintain and Service Non-Standard Custom Electric Thermal Oil Heaters?

- Are Electric Process Air Heaters Energy-Efficient?

- What Safety Features Should in a Non-Standard Custom Electric Thermal Oil Heater?

- What Are the Key Advantages of Using Electric Air Heaters Over Traditional Heating Methods?

- What Are the Benefits of Using Thermal Oil as a Heat Transfer Medium?

- How Does an Electric Process Air Heater Work?

- What Makes a Non-Standard Custom Electric Thermal Oil Heater Different from Standard Models?

- What Industries Benefit from Electric Process Air Heaters?

- Client feedback of Vacuum pyrolysis oven and preheat oven

- Suggestions for selecting electric thermal oil heater

- How to install and use the electric thermal oil heater

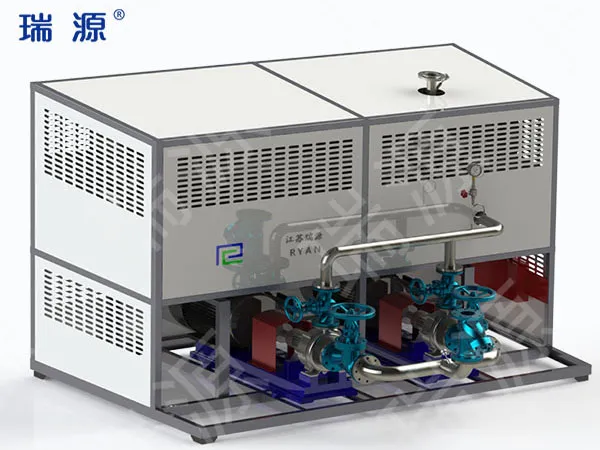

- Deliver five sets of explosion-proof organic fluid boiler with cool unit

What Safety Features Should in a Non-Standard Custom Electric Thermal Oil Heater?

17 Jun

In industrial operations involving high temperatures and combustible fluids, safety is paramount. This is especially true for non-standard custom electric thermal oil heaters, which are often tailored for demanding environments—such as chemical processing, pharmaceuticals, or hazardous areas where standard safety protocols may not suffice.

While every thermal oil system must include basic protection mechanisms, custom heaters require advanced, integrated safety features to match their unique configurations and risks. Whether you're specifying a new system or assessing an existing one, understanding which safety elements are essential can help you mitigate risks, meet regulatory requirements, and protect both personnel and equipment.

1. Over-Temperature Protection Systems

Over-temperature conditions are among the most critical hazards in thermal oil systems. Prolonged overheating can cause:

Fluid degradation or thermal cracking

Increased pressure in closed-loop systems

Fire hazards from fluid vaporization or leakage

To prevent this, a custom heater should include:

High-limit temperature switches or controllers: Independent of the primary temperature control, these shut off power if the oil temperature exceeds a preset safe threshold.

Multiple sensors (e.g., on the heater outlet and at the fluid return): Redundancy helps ensure a fail-safe shutdown in case of sensor error.

Automatic shutdown logic in the PLC or control system to isolate and power down the heater.

High-temperature cutoffs should be hardwired and tamper-proof, meeting local safety codes and providing fail-safe logic if digital systems fail.

2. Low-Flow and No-Flow Protection

Proper circulation of thermal oil is essential to prevent localized overheating of heating elements, which can cause:

Damage to heating coils

Fluid carbonization

Fire risks due to oil decomposition

Essential flow safety features include:

Flow switches or flow meters that monitor oil movement and trigger shutdowns if flow falls below a critical level.

Pump interlock systems: The heater should not energize unless the pump is running and confirmed by the flow switch.

Pressure sensors to detect pump cavitation, blockages, or seal failure.

For high-reliability systems, dual redundant pumps with automatic changeover can ensure continuous operation during pump maintenance or failure.

3. Thermal Expansion and Pressure Relief Systems

As thermal oil heats, it expands. Without proper pressure management, the system may become dangerously over-pressurized.

A non-standard custom heater must include:

An adequately sized expansion tank that accommodates the full range of fluid expansion and contraction, typically mounted above the loop.

Pressure relief valves (PRVs) on the heater and piping system, calibrated to open if system pressure exceeds safe operating limits.

Nitrogen blanket systems on closed expansion tanks to reduce oxidation and pressure fluctuations.

In systems with high temperature fluctuations, these features are crucial for both safety and fluid longevity.

4. Electrical and Control Panel Safeguards

Electrical systems are often a source of fire or failure if improperly managed. A well-designed custom heater should include:

Ground fault protection (GFCI or RCD) for personnel safety

Short-circuit and overload protection for each circuit or zone

Insulation monitoring to detect element deterioration or moisture ingress

Thermal imaging or temperature sensors inside the control panel to detect overheating components

Additionally, all control panels should be:

Lockable and weather-sealed

Rated for the environment (e.g., IP65 or NEMA 4X)

Equipped with emergency stop buttons accessible from outside

If the heater is located in a hazardous area, explosion-proof enclosures (ATEX, IECEx, UL Class I Div 1/2) are required.

5. Emergency Shutdown (ESD) and Manual Overrides

Custom electric thermal oil heaters often operate in high-value or high-risk processes. An Emergency Shutdown System (ESD) is crucial for quickly isolating the system in case of:

Fire Leak

Control system failure

Loss of power or process signal

Key ESD features include:

Remote and local ESD buttons located at strategic operator access points

Manual override valves and breakers

Fail-safe valve positioning (e.g., spring-return or normally closed valves) to stop oil flow automatically

Controlled cool-down routines to prevent oil coking or pipe rupture when shutting down a hot system

The ESD system should be integrated with the control logic, and its function should be tested routinely.

6. Leak Detection and Containment Systems

Though thermal oil systems are closed-loop, leaks can still occur due to aging gaskets, improper fittings, or over-pressure incidents. Thermal oils, especially synthetic ones, can ignite if they contact hot surfaces or electrical components.

Key containment and detection features include:

Leak sensors (optical or resistive) installed in drip pans or under piping

Double-walled piping or secondary containment

Oil catch basins or bunded skids

Automatic shutdown or alarm triggers in the event of a leak

In food or pharmaceutical industries, leak detection may also be required for cleanroom or product contamination protection.

7. Fire Safety and Suppression

If a leak coincides with a hot surface or an electrical short, fire is a serious risk. To address this, systems should include:

Non-combustible insulation materials on heaters and pipework

Automatic fire suppression systems (CO₂, FM-200, dry chemical) in enclosed heater areas

Flame arrestors or spark detectors in ventilation ducts if oil vapors are present

Integrated smoke or heat detectors tied to the main control system or plant fire panel

Using low-flammability or fire-resistant thermal fluids can further reduce the risk.

8. Lockout/Tagout and Maintenance Safety Features

During maintenance or troubleshooting, it's important to protect technicians from unexpected energization or oil release.

Key features to look for:

Mechanical lockout valves on oil inlet/outlet lines

Electrical disconnect switches on control panels

Purge systems to flush and cool the oil loop before access

Pressure bleed valves to depressurize the system before opening

Proper signage, lockout tagout kits, and system diagrams should also be provided for technicians.

9. PLC Safety Programming and Alarms

In custom-built systems with advanced PLCs and HMIs, safety must be coded directly into the logic, not just handled by mechanical devices.

Important features include:

Alarm priority levels (warning vs. critical)

Shutdown hierarchies (gradual or immediate depending on fault)

Redundant sensor checks and cross-verification logic

Automatic data logging of alarm history and shutdown events

These systems allow operators to act quickly and provide traceability for root cause analysis.

Conclusion

Non-standard custom electric thermal oil heaters offer unparalleled precision and adaptability, but they also demand a comprehensive approach to safety. From temperature and flow protection to explosion-proof designs and advanced PLC logic, the safety features of your heater must match the complexity and criticality of your application.

By ensuring these key systems are in place—and by working with experienced manufacturers who understand your industry—you can create a thermal oil heating system that not only meets performance goals but also prioritizes the safety of your people, equipment, and environment.