-

tel:

+86-15371113672 -

WhatsApp:

+86-15371113672 -

email:

qianli@jsryan.com

How Do You Maintain and Service Non-Standard Custom Electric Thermal Oil Heaters?

News List

- Petroleum and Gas

- How Do You Maintain and Service Non-Standard Custom Electric Thermal Oil Heaters?

- Are Electric Process Air Heaters Energy-Efficient?

- What Safety Features Should in a Non-Standard Custom Electric Thermal Oil Heater?

- What Are the Key Advantages of Using Electric Air Heaters Over Traditional Heating Methods?

- What Are the Benefits of Using Thermal Oil as a Heat Transfer Medium?

- How Does an Electric Process Air Heater Work?

- What Makes a Non-Standard Custom Electric Thermal Oil Heater Different from Standard Models?

- What Industries Benefit from Electric Process Air Heaters?

- Client feedback of Vacuum pyrolysis oven and preheat oven

- Suggestions for selecting electric thermal oil heater

- How to install and use the electric thermal oil heater

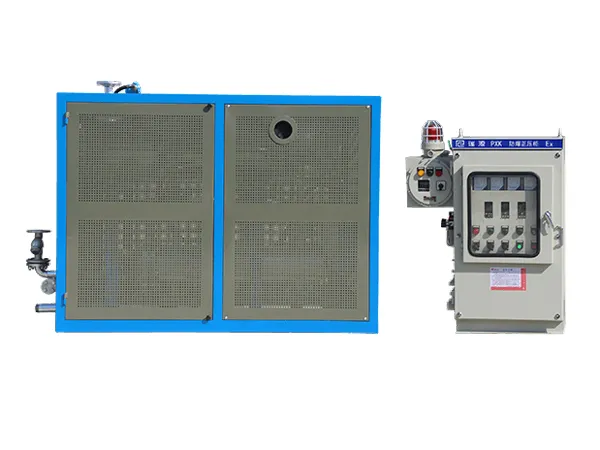

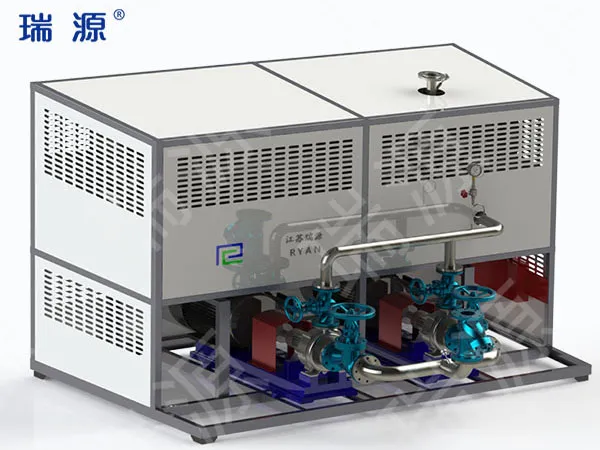

- Deliver five sets of explosion-proof organic fluid boiler with cool unit

20 Jun

Non-standard custom electric thermal oil heaters are highly specialized pieces of industrial equipment. Engineered to meet unique process demands, these heaters offer precise control, high efficiency, and adaptability in challenging environments. However, their performance and longevity depend heavily on proactive maintenance and proper servicing.

While standard maintenance protocols apply to all thermal oil heaters, non-standard custom units often include unique components, materials, or control systems that require specialized attention. In this guide, we’ll explore how to effectively maintain and service these advanced heating systems to ensure safe, reliable, and efficient operation.

1. Understand the System’s Custom Specifications

Before implementing any maintenance plan, it's essential to fully understand the system’s design and configuration, which may differ significantly from standard models.

Start by reviewing:

Engineering drawings and P&IDs (Piping and Instrumentation Diagrams)

Manufacturer’s operation and maintenance manuals

Custom control system documentation (PLC/HMI logic)

Electrical schematics and component specifications

Safety and compliance requirements (ATEX, UL, CE, etc.)

Because these heaters are tailored to specific applications, some may include features like multi-zone temperature control, redundant circulation pumps, or specialized thermal fluids. Understanding these customizations is critical for effective maintenance planning.

2. Routine Visual and Operational Inspections

Regular inspections help catch minor issues before they become serious problems. Visual checks should be done weekly or monthly, depending on the operating environment and usage intensity.

Key areas to inspect:

Heater body and insulation – Look for signs of oil leakage, corrosion, or physical damage.

Electrical connections – Check for loose terminals, discoloration, or overheating at contactors and terminals.

Circulation pump – Listen for unusual noises or vibration, which could indicate wear or cavitation.

Thermal fluid condition – Inspect for signs of degradation (smell, color change, residue).

Temperature sensors and gauges – Confirm proper readings and quick responsiveness.

Control panel – Check for fault codes, abnormal readouts, or alarm history.

If your heater is installed in a hazardous or outdoor area, include inspection of explosion-proof enclosures, seals, and environmental protection systems.

3. Monitor and Maintain Thermal Oil Quality

Thermal oil is the lifeblood of the system. Maintaining its quality is essential for efficient heat transfer and system reliability. Over time, thermal fluid can degrade due to oxidation, thermal cracking, or contamination.

Regular fluid analysis (typically every 6–12 months) should test for:

Viscosity changes

Acid number (TAN)

Flash point degradation

Carbon residue or sludge formation

Contaminants (water, particulates)

Based on test results, the maintenance team may need to:

Filter or flush the system

Top up or completely replace the fluid

Adjust temperature setpoints to reduce oxidation or cracking

Some custom heaters include inline filtration systems or bypass loops, which should also be cleaned and serviced regularly.

4. Calibrate and Test Temperature Sensors and Safety Devices

Non-standard heaters often use high-accuracy RTDs, thermocouples, and programmable safety limits to ensure precise thermal management. These sensors and controls must be calibrated periodically to prevent drift and inaccurate readings.

At least once a year, perform:

Sensor calibration against certified reference standards

Safety cutout tests for high-temperature and low-flow protection

Limit switch verification (for over-temp or under-temp scenarios)

HMI and PLC test routines for error detection and alarm responsiveness

Neglecting these checks can lead to overheating, reduced product quality, or even equipment failure.

5. Service Circulation Pumps and Expansion Tanks

Pumps are critical for maintaining flow rates and consistent heat transfer. Custom heaters may have variable-speed pumps, magnetically coupled units, or multiple pump circuits, which require special attention.

Pump maintenance tasks:

Check and lubricate motor bearings (if applicable)

Verify alignment and coupling integrity

Inspect seals for leaks

Clean filters or strainers in the fluid loop

Measure flow rate and pressure against design specs

Expansion tanks should also be monitored:

Check fluid levels, nitrogen blanket pressure, and vent valves

Inspect for corrosion, wear, or temperature-related degradation

Drain and clean if sludge buildup is observed

6. Maintain Electrical Components and Wiring

Custom heaters often operate at high voltages and use advanced control systems. Electrical maintenance is vital for safety and reliability.

Tasks include:

Thermal imaging to identify hot spots at terminals or circuit breakers

Torque checks on all connections (annually or biannually)

Cleaning contactors and relays with proper dielectric cleaners

Checking heaters’ resistance values to detect element deterioration

Inspecting VFDs or soft starters, if used, for overheating or faults

Control panels should be cleaned with compressed air and checked for ingress of dust, oil, or moisture.

7. Clean and Inspect Heating Elements

The heating elements (typically sheathed resistance heaters) can degrade over time due to scaling, coking, or corrosion—especially in custom systems operating at extreme temperatures.

Maintenance may include:

Measuring insulation resistance (megohm test) to ensure electrical integrity

Checking sheath condition for pitting, scaling, or discoloration

Cleaning carbon deposits or buildup using approved chemical methods

Verifying watt density remains within acceptable limits

Some high-end systems allow partial replacement of individual elements, reducing downtime and repair costs.

8. Backup Systems and Redundancy Checks

Custom heaters often include redundant components to ensure uptime—especially in mission-critical processes.

Maintenance should cover:

Testing backup pumps or heaters

Switching control modes from manual to automatic

Checking UPS power supply or battery backups

Simulating failure scenarios to confirm seamless transfer to redundant systems

Document all test results and corrective actions for traceability and audit purposes.

9. Software and Firmware Updates

Advanced non-standard heaters may use proprietary or OEM control software, with custom PLC logic or touch-screen interfaces. Keep software components up to date:

Update firmware to fix bugs or improve performance

Back up control logic and HMI screen configurations

Verify cybersecurity protocols (especially for network-connected systems)

Manufacturers often provide update schedules or remote diagnostic support. Follow their guidelines to keep systems secure and efficient.

10. Maintain a Detailed Service Log

Finally, a comprehensive service log is essential for managing long-term reliability and making data-driven maintenance decisions. The log should include:

Inspection checklists

Calibration records

Fluid analysis reports

Electrical test results

Spare parts replaced

Downtime incidents and corrective actions

This record helps in warranty claims, future troubleshooting, audits, and planning for end-of-life equipment replacement.

Conclusion

Maintaining and servicing non-standard custom electric thermal oil heaters requires a tailored approach that aligns with their specialized design, materials, and control systems. By following a structured maintenance program—focused on fluid quality, sensor calibration, pump and electrical inspections, and documentation—you can significantly extend equipment life, reduce operational risk, and improve process efficiency.

These systems are an investment in high-performance thermal processing. With the right care, they’ll deliver exceptional reliability and value for many years to come.

.webp)