-

tel:

+86-15371113672 -

WhatsApp:

+86-15371113672 -

email:

qianli@jsryan.com

Are Electric Process Air Heaters Energy-Efficient?

News List

- Petroleum and Gas

- How Do You Maintain and Service Non-Standard Custom Electric Thermal Oil Heaters?

- Are Electric Process Air Heaters Energy-Efficient?

- What Safety Features Should in a Non-Standard Custom Electric Thermal Oil Heater?

- What Are the Key Advantages of Using Electric Air Heaters Over Traditional Heating Methods?

- What Are the Benefits of Using Thermal Oil as a Heat Transfer Medium?

- How Does an Electric Process Air Heater Work?

- What Makes a Non-Standard Custom Electric Thermal Oil Heater Different from Standard Models?

- What Industries Benefit from Electric Process Air Heaters?

- Client feedback of Vacuum pyrolysis oven and preheat oven

- Suggestions for selecting electric thermal oil heater

- How to install and use the electric thermal oil heater

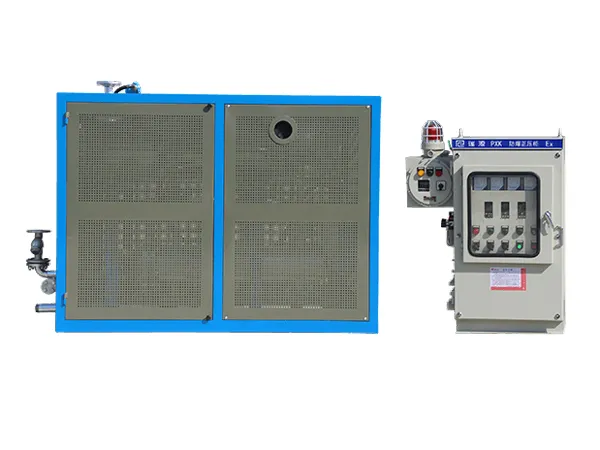

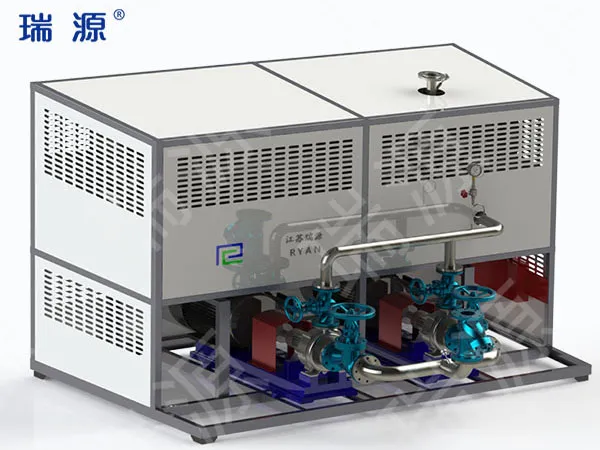

- Deliver five sets of explosion-proof organic fluid boiler with cool unit

Are Electric Process Air Heaters Energy-Efficient?

19 Jun

Electric process air heaters are generally energy-efficient, especially when compared to traditional fuel-based heating systems. Here's why:

1. High Efficiency Conversion

Electric heaters convert almost all of the electrical energy into heat. In fact, their efficiency can be close to 100%, as there is little to no energy loss in the form of exhaust gases, as is common in gas or oil heaters. This makes them one of the most efficient types of heating solutions available.

2. Zonal Heating Efficiency

Electric process air heaters can be used for zonal heating, meaning they only heat the area or air that needs it. This reduces unnecessary heating and saves energy. For example, instead of heating an entire facility, heaters can be placed directly in the production line where heat is needed most.

3. Low Thermal Losses

Because electric heaters don’t rely on long ducting or complex piping systems (like boilers and furnaces), there’s less opportunity for heat loss. The heated air is delivered directly to the area of application, improving efficiency.

4. Integration with Smart Controls

Modern electric air heaters often include intelligent control systems that optimize energy use. With features such as timers, occupancy sensors, and programmable thermostats, energy use can be precisely regulated, further improving overall efficiency.

5. Maintenance-Free Operation

Low maintenance requirements contribute to operational efficiency. With fewer parts that wear out and no combustion process, electric heaters have longer service intervals and reduced downtime, which contributes indirectly to energy and cost savings.

6. Environmentally Friendly

In regions where electricity comes from renewable sources, electric process air heaters are a green alternative. Even where electricity is generated from fossil fuels, the high efficiency of electric heaters offsets a significant amount of the environmental impact.

.webp)