-

tel:

+86-15371113672 -

WhatsApp:

+86-15371113672 -

email:

qianli@jsryan.com

What Are the Benefits of Using Thermal Oil as a Heat Transfer Medium?

News List

- Petroleum and Gas

- How Do You Maintain and Service Non-Standard Custom Electric Thermal Oil Heaters?

- Are Electric Process Air Heaters Energy-Efficient?

- What Safety Features Should in a Non-Standard Custom Electric Thermal Oil Heater?

- What Are the Key Advantages of Using Electric Air Heaters Over Traditional Heating Methods?

- What Are the Benefits of Using Thermal Oil as a Heat Transfer Medium?

- How Does an Electric Process Air Heater Work?

- What Makes a Non-Standard Custom Electric Thermal Oil Heater Different from Standard Models?

- What Industries Benefit from Electric Process Air Heaters?

- Client feedback of Vacuum pyrolysis oven and preheat oven

- Suggestions for selecting electric thermal oil heater

- How to install and use the electric thermal oil heater

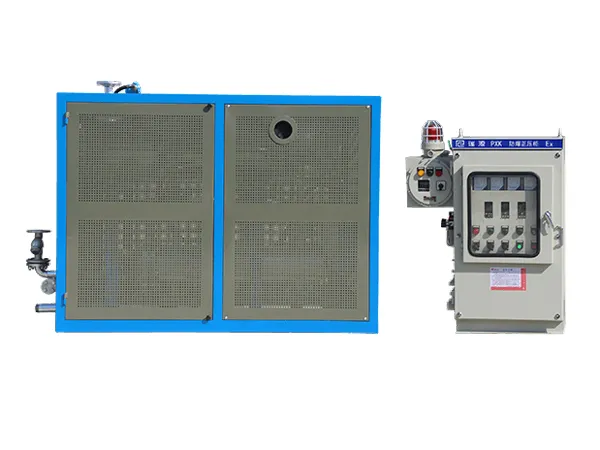

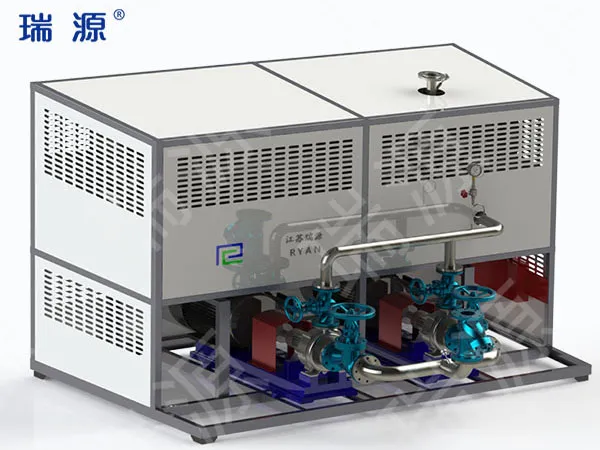

- Deliver five sets of explosion-proof organic fluid boiler with cool unit

What Are the Benefits of Using Thermal Oil as a Heat Transfer Medium?

12 Jun

In industrial heating systems, choosing the right heat transfer medium is critical to the efficiency, safety, and effectiveness of the process. While steam and water have traditionally been used, thermal oil (also known as heat transfer fluid or HTF) has increasingly become the preferred choice across many sectors, including chemical processing, pharmaceuticals, food manufacturing, plastics, and textiles.

So, what makes thermal oil such a valuable and versatile heat transfer medium? The answer lies in its high-temperature capability, thermal stability, low maintenance needs, and excellent energy efficiency. Let’s explore these and other advantages in detail.

1. High-Temperature Capability at Low Pressure

One of the most significant advantages of thermal oil is its ability to operate at very high temperatures without the need for high system pressure. For example, many thermal oils can safely operate at temperatures of 300°C to 400°C (572°F to 752°F), while maintaining system pressures below 5 bar (72 psi).

By contrast, steam systems require pressures above 100 bar (1,450 psi) to reach those same temperatures, which increases equipment cost, safety risks, and regulatory requirements.

Benefits of low-pressure, high-temperature operation include:

Reduced risk of explosion or catastrophic failure

Simpler piping and valve design (no high-pressure ratings needed)

Lower insurance costs and fewer regulatory hurdles

Easier system startup and shutdown procedures

This makes thermal oil systems ideal for industries that need consistent, high-temperature heat without the complications of steam-based systems.

2. Excellent Thermal Stability

Modern synthetic and mineral-based thermal oils are engineered to be thermally stable over long periods of use. This means they resist breakdown and degradation even after thousands of hours of continuous high-temperature operation.

Thermal stability is crucial because it ensures:

Consistent heat transfer properties over time

Reduced carbon buildup or sludge formation in pipes and heaters

Lower maintenance frequency and operating costs

Extended fluid life, often up to 5–10 years with proper filtration and monitoring

This stability contributes significantly to plant uptime and reduces the frequency of fluid replacement, making thermal oil an economical long-term choice.

3. Energy Efficiency

Thermal oil systems are typically more energy-efficient than steam systems in many applications. Reasons include:

No phase change energy loss: Unlike steam, which must be condensed after transferring its heat, thermal oil remains in liquid form throughout the heating cycle. There’s no energy lost to condensation or evaporation.

Lower system losses: Because thermal oil systems operate at low pressure, less energy is required to circulate the fluid. Additionally, well-insulated systems minimize heat loss.

Faster heat-up and recovery times: With high thermal capacity and excellent flow characteristics, thermal oil heats up quickly and can recover from load changes faster than water- or steam-based systems.

These factors lead to lower energy consumption per unit of heat delivered, reducing operational costs and environmental impact.

4. No Freezing or Scaling Risks

Unlike water or steam, thermal oil does not freeze under normal ambient conditions, making it ideal for outdoor or unheated facilities.

Water freezes at 0°C (32°F) and can cause system damage if not properly drained or heated during shutdowns.

Thermal oil remains stable at temperatures as low as -20°C (-4°F) or lower, depending on the formulation.

Additionally, thermal oil systems do not suffer from scaling, corrosion, or mineral deposit formation, which are common problems in water-based systems. This eliminates the need for water treatment chemicals, softeners, or blowdown procedures.

5. Minimal Maintenance Requirements

Thanks to the stable nature of thermal oils and the lack of high-pressure components, thermal oil systems require less maintenance than comparable steam systems.

Key maintenance advantages include:

No boiler inspections or pressure vessel certifications required in most jurisdictions

No corrosion monitoring or water chemistry management

Fewer mechanical failures due to low operating pressures and simpler system components

Easier leak detection and repair, since oil leaks are more visible than steam loss

This results in fewer shutdowns, lower labor costs, and improved system reliability over the life of the equipment.

6. Precise Temperature Control

Thermal oil systems offer fine-grained temperature control, typically within ±1°C (±1.8°F). This level of precision is essential for applications where temperature consistency is critical, such as:

Plastic extrusion and molding

Pharmaceutical batch processing

Food drying and baking

Chemical reactions requiring tight thermal profiles

Because there is no phase change, the heat transfer remains smooth and predictable, which contributes to consistent product quality and reduced scrap rates.

7. Versatility Across Applications

Thermal oils are available in a wide range of formulations—synthetic, aromatic, mineral-based, and silicone-based—each designed to suit specific applications, including:

High-purity environments such as food, beverage, and pharmaceuticals

Chemical-resistant fluids for aggressive or reactive processes

High-temperature thermal fluids for metal treatment or asphalt heating

Low-viscosity oils for fast-cycling heating systems

This makes thermal oil a highly adaptable medium that can be matched precisely to the operational and safety requirements of each industry.

8. System Flexibility and Integration

Thermal oil heaters can be easily integrated into multi-zone heating systems, heat exchangers, or batch process lines. A single heater can support multiple circuits with different temperature requirements through control valves and flow regulators.

Thermal oil systems also allow for:

Reversible heat flow, ideal for applications needing both heating and cooling

Indirect heating, where sensitive materials must not contact the heating elements

Heat recovery, where excess heat from one part of a process can be reused elsewhere

This flexibility is challenging to achieve with steam systems, especially when precision and modularity are required.

9. Safer Operation

Although thermal oil is flammable, modern systems are designed with multiple safety features, such as:

Over-temperature protection

Flow monitoring and pump interlocks

Thermal expansion tanks with pressure relief valves

Fire-resistant fluid options and insulated pipework

Most importantly, the absence of high-pressure steam reduces the risk of catastrophic equipment failure. Thermal oil systems, when properly designed and maintained, are safe and reliable even in demanding environments.

10. Environmental and Regulatory Benefits

Thermal oil systems can also support sustainability and environmental goals:

Reduced water consumption, as no steam is vented or condensed

Lower CO₂ emissions per unit of heat due to energy efficiency

Less need for chemical treatments and waste disposal compared to water-based systems

Some modern fluids are biodegradable or non-toxic, enhancing environmental safety

Because of these features, thermal oil systems are often chosen in eco-conscious industries and green-certified facilities.

Conclusion

Using thermal oil as a heat transfer medium offers a compelling range of benefits over traditional steam or hot water systems. With its ability to operate at high temperatures with low pressure, excellent thermal stability, energy efficiency, and minimal maintenance requirements, thermal oil is the ideal choice for industries that demand safe, reliable, and precise thermal control.

Whether you're looking to improve process performance, reduce operational costs, or enhance safety and compliance, thermal oil heating systems provide a modern solution to a wide variety of industrial challenges.