- E-mail: qianli@jsryan.com

- whatsapp: +86-15371113672

|

Model |

Chamber Dimension |

Overall Dimension |

Heating Power |

Vacuum Pump |

Vacuum Degree |

Pumping Speed |

|

GYZ-L-1 |

Φ500X600 |

1700X1200X1850 |

9 |

2.2 |

-0.085 |

80 |

|

GYZ-L-2 |

Φ600X800 |

2400X1600X2300 |

15 |

3 |

-0.085 |

80 |

|

GYZ-L-3 |

Φ700X1000 |

2400X1900X2500 |

18 |

3 |

-0.085 |

80 |

|

GYZ-L-4 |

Φ800X1000 |

2750X2100X2500 |

30 |

4 |

-0.085 |

80 |

|

GYZ-L-5 |

Φ800X1200 |

2750X2100X2800 |

30 |

4 |

-0.085 |

80 |

|

GYZ-L-6 |

Φ1000X1200 |

2950X2200X2800 |

30 |

4 |

-0.085 |

80 |

|

GYZ-L-7 |

Φ1000X1400 |

2500X2950X3000 |

42 |

4 |

-0.085 |

80 |

|

GYZ-L-8 |

Φ1000X2000 |

3250X2150X3600 |

60 |

4 |

-0.085 |

80 |

-

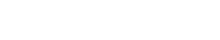

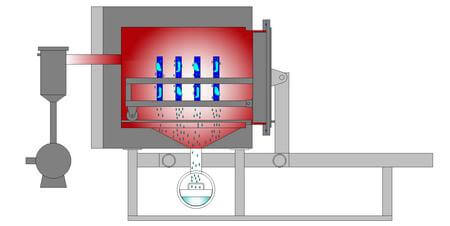

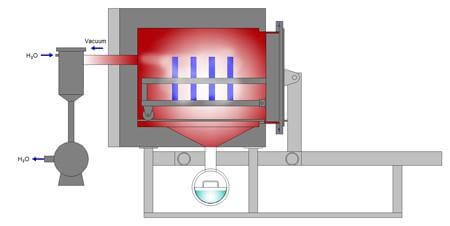

High thermal efficiency and low consumption

1 -

Easy opration and automatic

2 -

The workpiece will be cleaned well with smooth wire hole

3 -

Temperature raise fast and even inner temperature of furnace

4 -

Convenient inspection and maintenance

5 -

Environmental protection, energy saving, security and stability

6

- Filter mesh cleaning

- Breaker plates cleaning in plastic industry

- Spinneret plate cleaning

- Screw and die head cleaning

- Mesh cleaning in polymer industry

- Mold cleaning in plastic industry

- Spinning pack cleaning

- Spinning nozzle cleaning

- Extrusion tool cleaning

- Laser filter cleaning

- Cleaning polymer, PE, PP, polyester, nylon from filter net

Delivery & Package

-

Delivery time: Machine will be shipped within 30 working days (or on request) after payment, our technician will test the machine well before shipment, so our customers can use directly when got the machine.

-

Packing: plywood case. Machine will be wrapped with plastic film and then put into plywood cases before cleaning.