Product Description

-

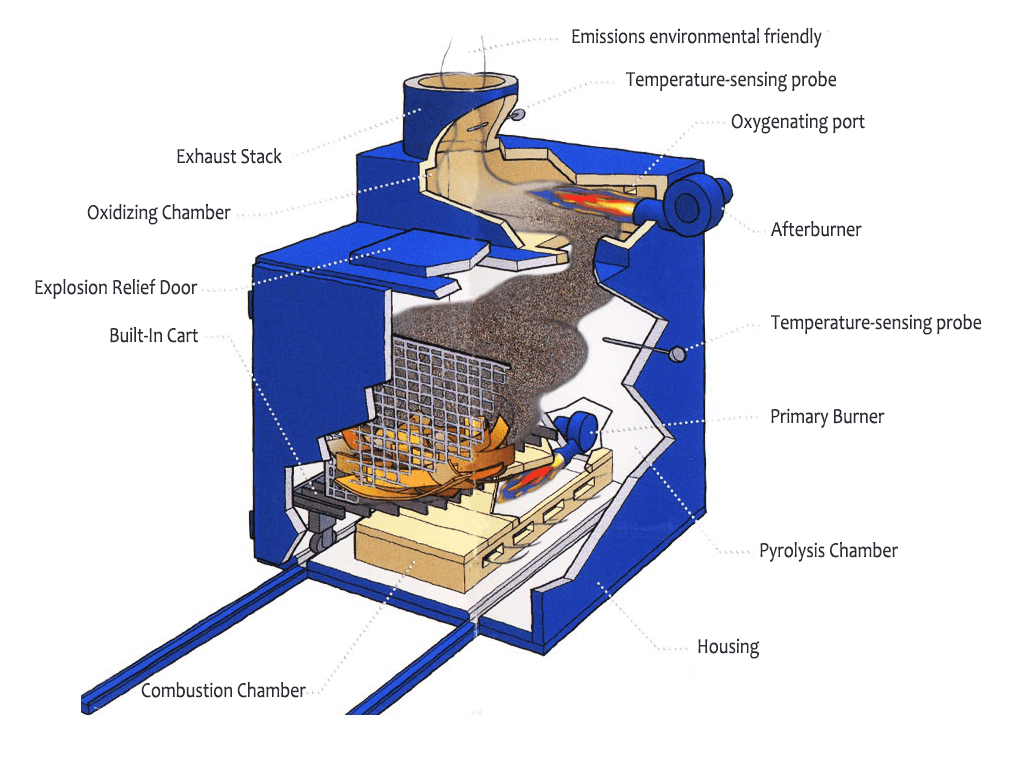

Paint Stripping Oven are used frequently in the coatings, fibers, electric motors and plastics industry. Burn off ovens are designed for removing paint, powder coating, epoxies, lacquers, urethanes and other organic or inorganic compounds from a variety of parts, such as: racks, hooks, jigs, fixture. And also for cleaning polymers from a variety of metal parts, such as: moulds, extrusion dies, screws, nozzles, extruders, hot runners, breaker plates.