1.Safety Instruction

Thanks for purchasing this product from our company!

Please take care of this manual and ensure you have fully read this manual before operation .

DANGER:

Do not place the machine in the places where have flammable and explosive

materials.

Make sure it’s off power before carry, connection, test.

Do not touch any electric terminal when the machine is running.

Wet hand is not allowed to touch the machine.

Do not touch any exposed conductive part of the machine.

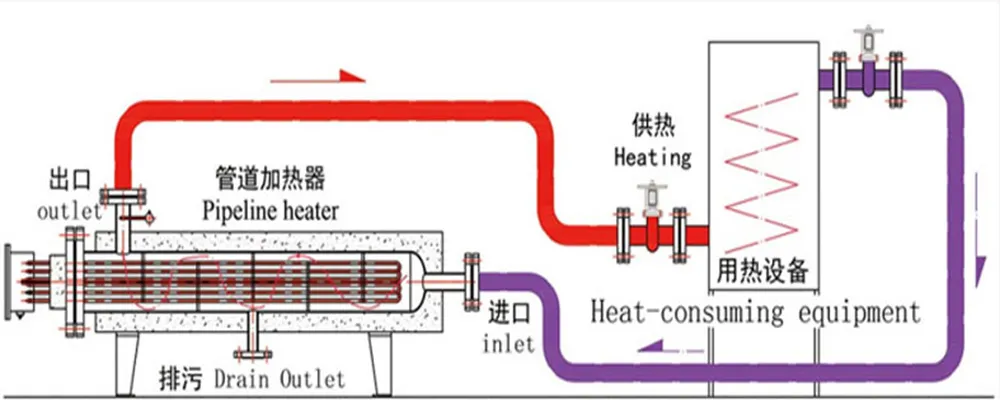

2.Rationale

The air is forced into the air heater by the air compressor,and the max temperature of the air can reach to 350℃,the temperature can be adjust by the temperature controller.

The signal of the outlet temperature is provided by the thermocouple which is installed in the outlet pipe.

When the temperature controller received the signal from the thermocouple, then the temperature controller will drive the SCR to work.

There’s another thermocouple which is installed in the flange heater, once the heater overheat, the thermocouple would output the signal and then the heater would shut down automatically.

Power: 380V 50Hz.

3.Specification

Medium: air

Flow: 1800m3/h

Working pressure: 0.15Mpa

Design pressure: 0.19Mpa

Working temperature: inlet - 20℃, outlet - max 350℃

Heating power: 300KW

Power: 380V 50Hz, 3 phase

Heating element: ‘U’ type, 3600W, 90pcs, 2.05W/cm2(6 pcs for spare)

Qty.: 2 sets

Work place: Indoor

Control cabinet: Indoor

Weight: 1500KG

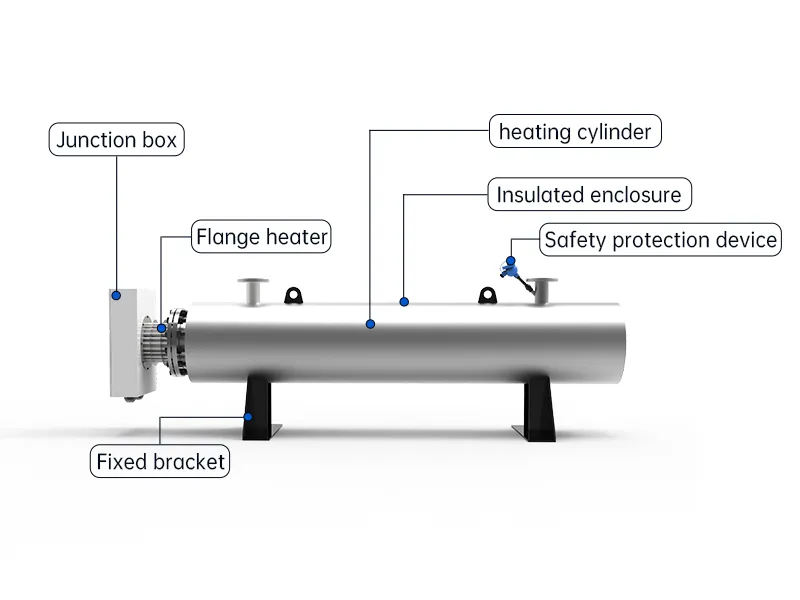

4.Structure

The whole air heating system includes heating elements, flange heaters, terminal box, barrel and the control cabinet.

The flange heater is installed in the barrel, and the terminal box was combined with the flange heater.

The heating barrel: stainless steel seamless pipe.

The flange heater

Shell: stainless steel

Resistance wire: Cr20Ni80

withstand voltage:1800V/min

Sealing gasket: Spiral Wound Gasket

Thermal insulation layer: alumina silicate fiber, thickness≥150mm.

.webp)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)