- Working Principle

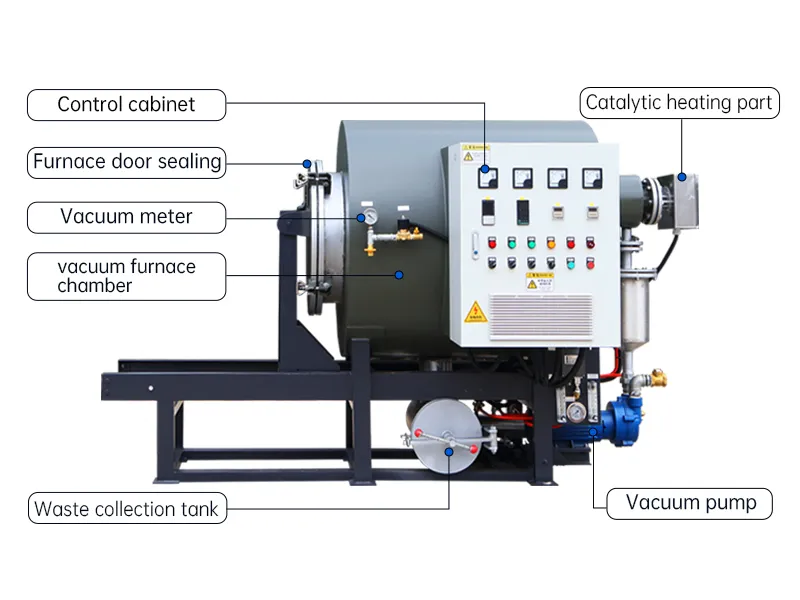

Vacuum pyrolysis cleaning oven makes use of the characteristics of polymer which can be melted at about 300°C and can be cracked and coked by isolated air above 300°C, producing a variety of lysates. Above 400 °C with little oxygen and much vacuum, can be fully oxidizable.

|

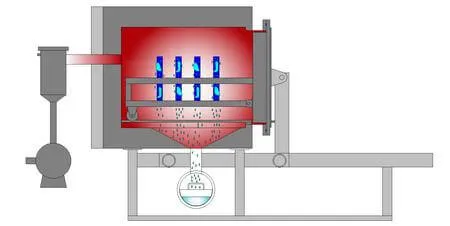

I. Melting Phase The parts to be cleaned are heated to 320°C in the chamber. After this process, most of the polymer melts and drains into the waste collection tank. |

|

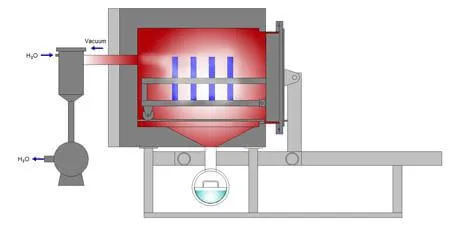

II. Pyrolysis Phase The furnace chamber temperature will rise to 450C and maintain it for several hours. The unmelted Polymer during the first phase will be pyrolyzed and vaporized in a vacuum environment. The generated gases will go through the secondary catalytic part and water spray system. The condensates are collected and rush out with water. |

|

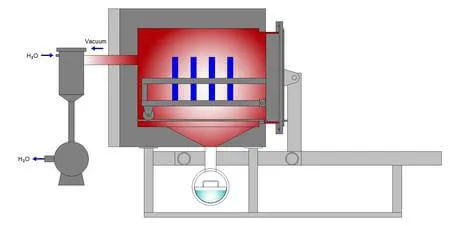

III. Oxidation Phase In the last one hour, the solenoid valve will open automatically and let a small amount of air enter. Remaining polymer that still exist after the pyrolysis phase will be burnt under vacuum and limited air. |

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)