-

The main use of flanged immersion heaters is the heating process, especially for heating tanks, oil containers, food processing equipment, and gases and liquids in cleaning and rinsing tanks. Direct immersion is an effective process. However, the choice of flanged heater depends on 1) evaluation requirements such as heat (or watt density), voltage, operating environment, such as the type of fluid used (water or corrosive solution) and 2) selection of the most appropriate method Blue heaters, depending on flange size and material, component count, kilowatt rating, terminal housing and jacket material.

-

The process engineer applies his/her knowledge and acumen to select and install the flange heater. Flanged heaters are typically bolted to mating flanges that are welded to the tank wall or nozzle. The maximum sheath temperature of the component material is a very important parameter.

-

It depends on:

●viscosity

●specific gravity

●corrosiveness of the heating medium

●contaminants (if any) present in the heating medium

●corrosion resistance of the sheathing material

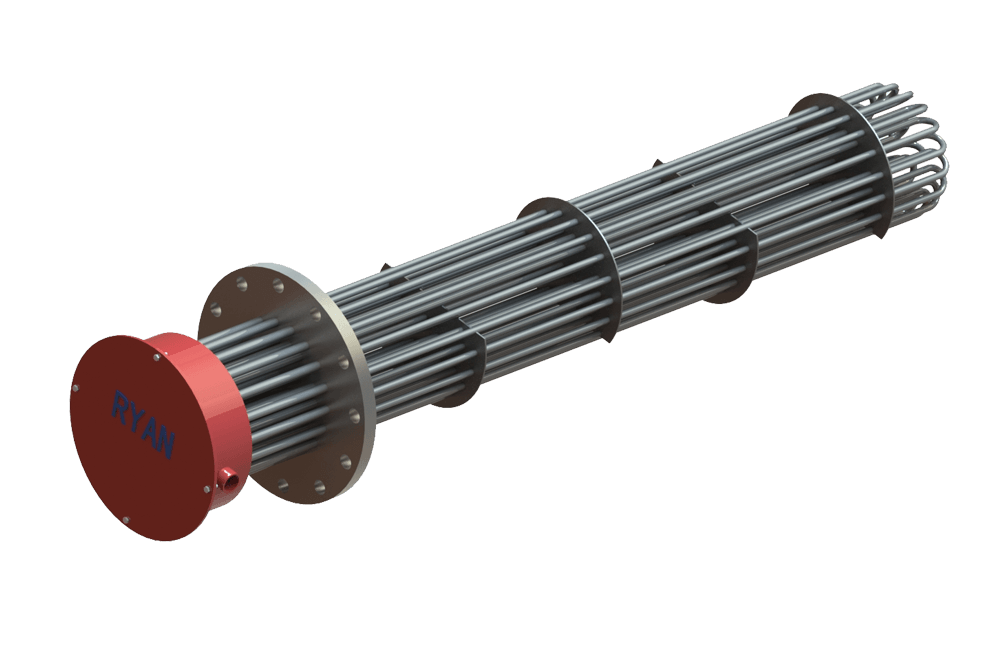

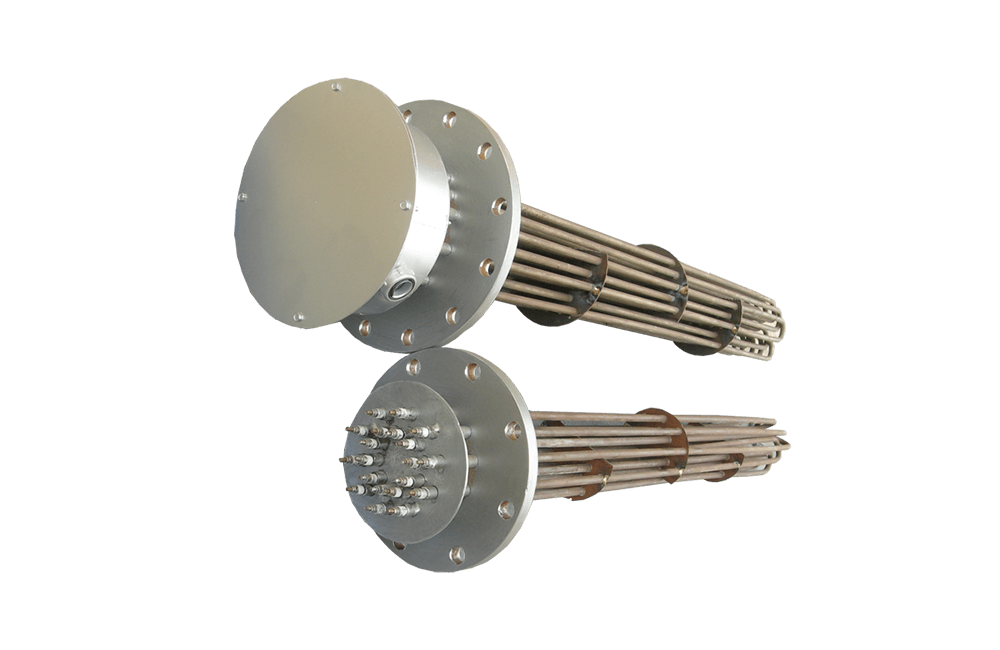

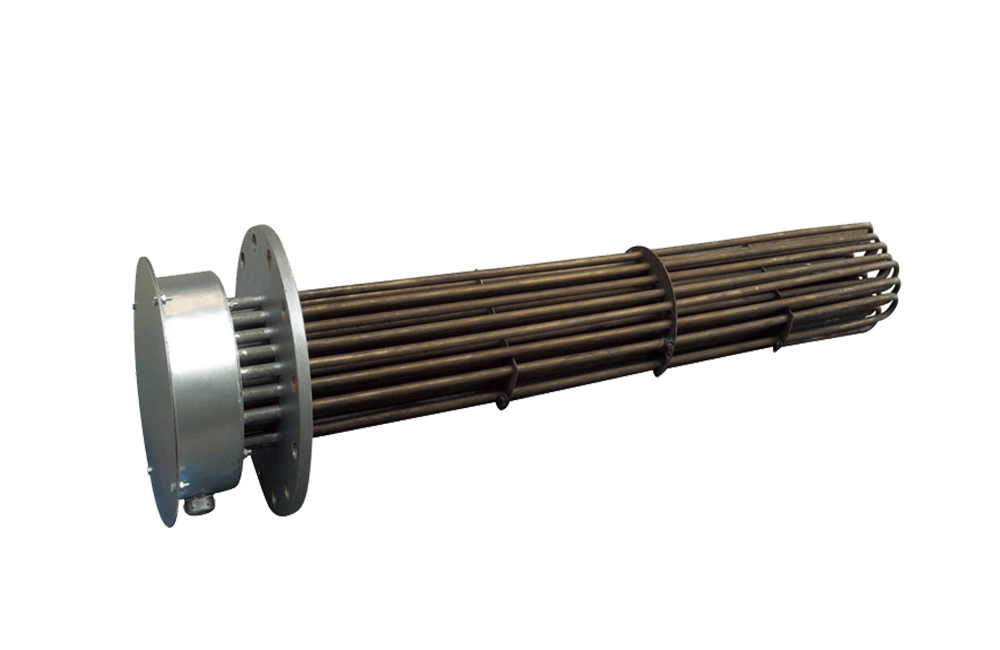

Flange Heater

Flange Heater

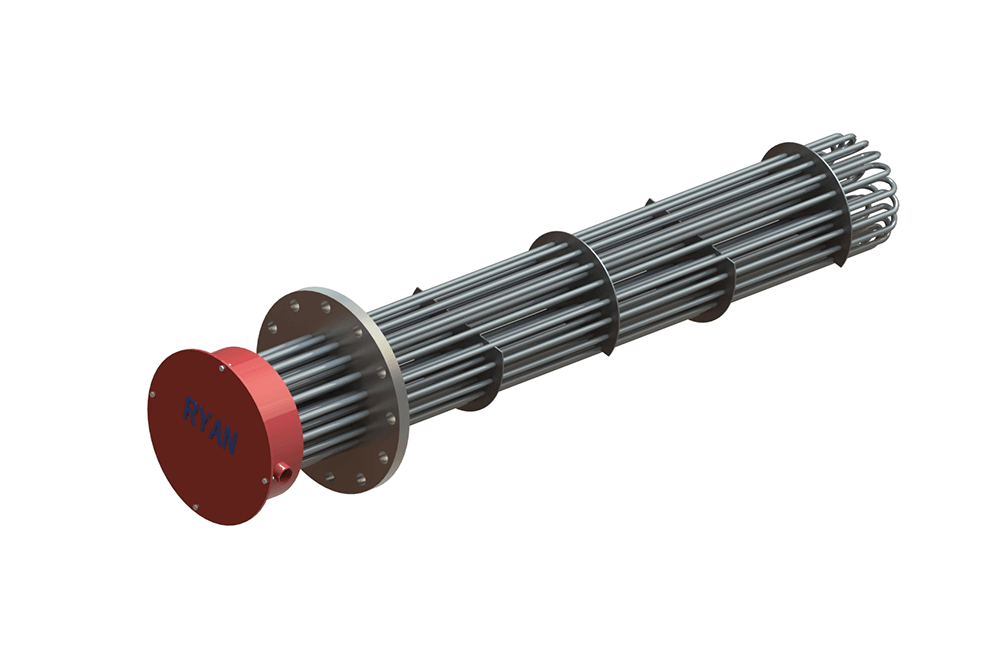

The flanged immersion heater is used for heating gases and liquids such as: water, oil and gas and corrosive solutions, which has hairpin or bent tubular elements.

- E-mail: qianli@jsryan.com

- whatsapp: +86-15371113672

The flanged immersion heater is used for heating gases and liquids such as: water, oil and gas and corrosive solutions, which has hairpin or bent tubular elements. They are manufactured by welding or brazing these heating elements onto a flange. Rated flanges are usually made of steel and are ideal for industrial process heating. However, other materials such as stainless steel are also used. Jacking materials for heating elements include: steel, stainless steel, and copper.

Flange immersion heaters come in different jacket and flange materials, different operating voltages, power (kW) ratings and temperature ranges.

For electrical connections, flange heaters also include different types of junction boxes. Each type identifies its suitability for different scenarios, such as a wet operating environment.

Feedback from contact with us